Processing Piping Contractors

Our process piping Contractors at SST-PV

Our in-house process piping contractors are highly skilled sanitary process pipe welders, fitters, millwrights, riggers, and mechanics.

SST-PV offers a complete process piping services, from small repair jobs to complete mechanical and process installations.

Our Process piping staff works with our design engineers, ensuring that the system function is true throughout the installation process and initial startup.

Our process piping professionals are more than installers; they understand process systems and how every piece of sanitary tubing, every fitting, every weld, serves the overall system.

Projects

All types of stainless-steel process piping projects.

SST-PV can assist with your stainless-steel process piping installation. That includes pipe material selection, pipe routing design, pipe support design and installation. We also can help with selection of valves both manual and control, P&ID development and implementation, pipe testing, pipe finishing and labeling, and pipe insulation and heat tracing. Our highly qualified pipefitters follow all the code requirements applicable.

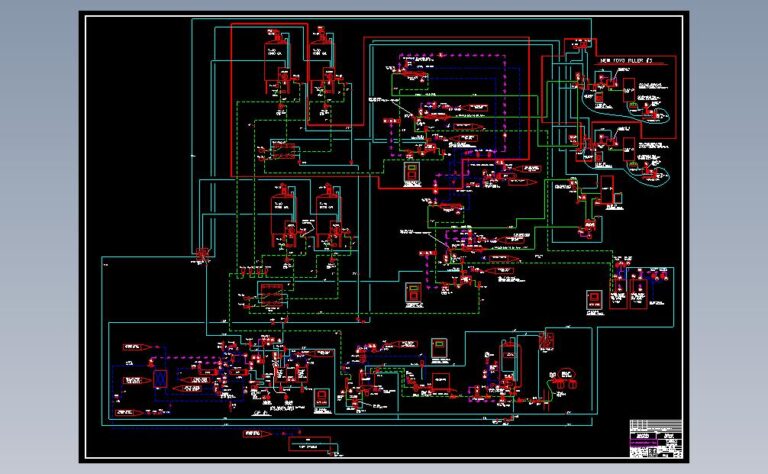

P&ID DEVELOPMENT

Stainless Steel Process Piping & Instrumentation Drawing (P&ID)

Preparation is necessary to instruct the pipefitters of the proper process flow. SST-PV can create a P&ID or revise a P&ID for implementation if required. SST-PV will create pipe routing and install the piping from P&ID as required by clients. Piping layout, routing, creating, revision, and installation of all process piping are standard procedures for SST-PV.

SST-PV, and its subcontractors can design and install quality Electrical & Control systems as the project requires. The design and build of programmable logic controllers (PLC) and Control Panels are performed as required.

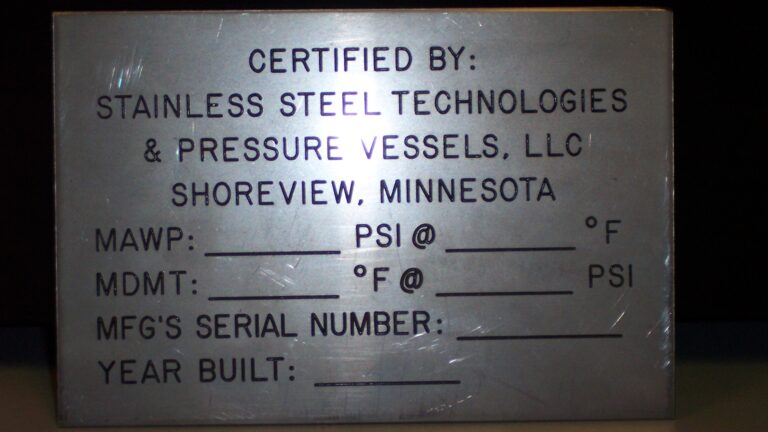

Stamp authorizations

We carry both ASME “S” and NBIC “R” stamp authorizations which provide us with the authority to manufacture and assemble power boilers and associated components and pressure piping as well as to perform repairs and alterations to boilers and pressure vessels.

Our fabrication shop works with all pipe sizes. In addition to stainless and carbon steel, we work with all alloys as well as aluminum, copper, and plastic piping.

SST-PV welders are proficient and ASME certified in TIG, MIG, SMAW & Orbital Welding techniques. Our methods of quality control include dye penetrant as well as X-Ray technologies our methods include our Q.C. of welding using dye penetrant, ultrasound, x-ray for weld inspection.

Stainless Steel Processing Pipe fabrication shop

Our pipe fabrication shop is designed to support our field operations as well as provide custom fabrications for clients. Pre-fabrication of your piping in our shop reduces the field installation time and improves project efficiency. We are proud of our ability to provide your pipe fabrication and installation requirements on time and on budget.

Whether it is welded pipe or tube, threaded piping, chemical welding, or bending tubing; our craftsmen will get the job done.

We have vast experience with food grade piping. Ultra clean TIG welding and orbital welding which ensures systems that keep product safe and within standards. Our craftsmen and estimators are trained with food safety standards in mind.

SST_PV process piping service also include:

- Sanitary stainless-steel fabrication, stainless steel type 304, 316 material standards

- High-purity installation for aseptic and pharmaceutical products

- Specialty alloys, include Duplex, Titanium and Hastelloy

- Field surface preparation abelites to all sanitary standards

- Orbital welding capabilities

- 3A sanitary process piping

- USDA- compliment installations

- tuning and optimization

- Vessel’s repair

- Dye Checking

- Utility Piping

- Confined space service

- SST-PV has conducted process piping on the full range of our system offerings, our applications include:

- plant-wide process

- utility piping installation projects

- Sanitary beverage flow plates and distribution circuits

- Piping structural racks for silo alley

- All polished and unpolished powered conveyance lines

- Stainless steel piping for all sanitary applications

- Jacket and insulated tubing lines and fittings

- Flow plates, Swing jumpers and headers

- Sanitary tubing installation for silo jacket cooling water

- All valves and piping for tank to mixing kettles automation.

The Industries we serve:

Animal Health, Beverage, Biodiesel, Chemical, Dairy, Ethanol, Energy, Food and Pharmaceutical.